Poly(methyl methacrylate) (PMMA), also known as acrylic or acrylic glass.PMMA is a strong and lightweight material. It has a density of 1.17–1.20 g/cm3 which is less than half that of glass.It also has good impact strength, higher than both glass and polystyrene; however, PMMA’s impact strength is still significantly lower than polycarbonate and some engineered polymers. PMMA ignites at 460 °C (860 °F) and burns, forming carbon dioxide, water, carbon monoxide and low-molecular-weight compounds, including formaldehyde.

PMMA transmits up to 92% of visible light (3 mm thickness), and gives a reflection of about 4% from each of its surfaces due to its refractive index (1.4905 at 589.3 nm).It filters ultraviolet (UV) light at wavelengths below about 300 nm (similar to ordinary window glass). Some manufacturers add coatings or additives to PMMA to improve absorption in the 300–400 nm range. PMMA passes infrared light of up to 2,800 nm and blocks IR of longer wavelengths up to 25,000 nm. Colored PMMA varieties allow specific IR wavelengths to pass while blocking visible light (for remote control or heat sensor applications, for example).

PMMA swells and dissolves in many organic solvents; it also has poor resistance to many other chemicals due to its easily hydrolyzed ester groups. Nevertheless, its environmental stability is superior to most other plastics such as polystyrene and polyethylene, and PMMA is therefore often the material of choice for outdoor applications. Tensile strength decreases with increased water absorption. Its coefficient of thermal expansion is relatively high at (5-10)×10−5 K-1. PMMA has a maximum water absorption ratio of 0.3–0.4% by weight. Tensile strength decreases with increased water absorption.

The common impression of PMMA is transparent and glass like hard plastics. Do you know how the raw material looks like under microscope? EPRUI supplies monodisperse PMMA microspheres which is white powder and with uniform spherical particles under microscope.

1. Light diffusion use

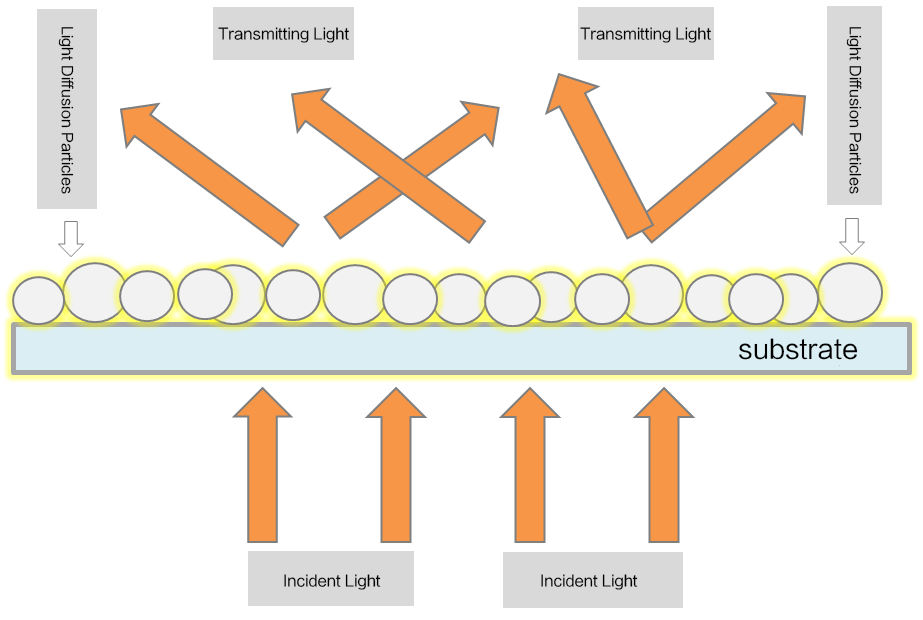

PMMA microspheres can be used for light diffusion application.PMMA microspheres by EPRUI have perfect roundness, precise particle size, and very narrow particle size distribution. With their outstanding powder flow properties, high dispersibility in application media, good thermostability and weatherability, our PMMA microspheres are widely used in many different fields such as LED lighting fixtures, LCD light diffusion sheet and film…

2. Coatings and Paints

Cross-linked PMMA beads are perfect as functional additives such as decorative and exterior paints, clear wood coatings, varnishes, metallic paints, flooring and paneling lacquers. PMMA microspheres can be used in water based decorative and interior paint formulations to obtain super matte paints, even for dark colors, combined with excellent side sheen control, good scratch resistance and a surface film which is durable and easy to clean.

PMMA micropowder added in clear water based wood coatings give a uniform scattering of light that closely matches the resin systems. This results in superior film clarity with no haze and with excellent scratch and stain resistance. PMMA microspheres are widely used in high end industrial coatings for texture effects, gloss control and improved scratch resistance.

PMMA beads are inert in most solvents are easily dispersed in aqueous solutions.

3. Thermoplastics

PMMA microspheres are added to thermoplastics polymers such as engineered compounds and masterbatches. The addition of well-defined sized beads to a masterbatch results in an effective scattering and diffusion of light without significantly reducing light transmission. Such light diffuser masterbatches are suitable for a variety of applications such as diffusers for ceiling lighting systems, lightening panels, cell phones, architectural lighting fixtures, and signs.

Another application in plastics is the usage of polymer beads as anti-blocking agents. The beads creates space between the film layers by sticking out from the film surface creating “little bumps”, which help to minimize the film to film surface contact, increasing the distance between the two layers, thereby minimizing blocking.

In film extrusion applications, our PMMA powder can be added to create matte films with an even surface and well defined scattering of light.

4. Cosmetics

Crosslinked PMMA spheres with a diameter of 6 micron are specially designed for use as additives in cosmetics and toiletries. The uniform particle distribution gives cosmetic products unique flow properties and a soft touch feel. The low residual monomer content ensures a product free of smell. It is approved according to EU-directives for use as an additive in cosmetics and toiletries.

5. Dermal Fillers

PMMA dermal filler is considered semi-permanent, and is most often used to treat medium-to-deep wrinkles, folds and furrows, particularly nasolabial folds. It can also be used to fill out pitted scars and to augment thin lips.

When a more permanent solution to facial wrinkles is desired, PMMA microbeads are often used instead of collagen replacement therapy or hyaluronic therapy. PMMA has been used for many years in permanent surgical implants. Because of this, your surgeon will likely under-fill on the first treatment, adding more later if needed.

6. Calibration

EPRUI supply monodisperse PMMA microspheres which follows high precision calibration standards composed of cross-linked polystyrene, which ensures good durability and chemical resistance. Typical applications are calibrations of instruments, machinery, optical electronic equipment and laboratory equipment such as particle analyzers and sieves.